Sale of non-freon commercial refrigerators for CO2 refrigerant

Commercial (SCM) refrigerator sales

Non-Freon Refrigeration Equipment Document Download

Refrigeration unit that is friendly to both running costs and the environment

We propose various CO2 transitional critical condensation units that emit extremely little carbon dioxide and reduce energy consumption compared to conventional HFC refrigerants.

SCM Frigo’s sole distributor in Japan

In February 2020, SCM Frigo (Italy), a major European manufacturer of commercial refrigerators, signed an exclusive agency contract for sales in Japan.In addition to the production of food processing equipment so far, we have started selling a new non-freon commercial refrigerator that uses carbon dioxide gas refrigerant.

Currently, refrigerating and refrigerating equipment installed in food factories and freezer warehouses generally uses chlorofluorocarbon refrigerant, which has a global warming potential several thousand times that of carbon dioxide.

On the other hand, refrigerators we handle are carbon dioxide gas refrigerants,which has few troublesome and less initial investment beyond the other non freon refrigerants.

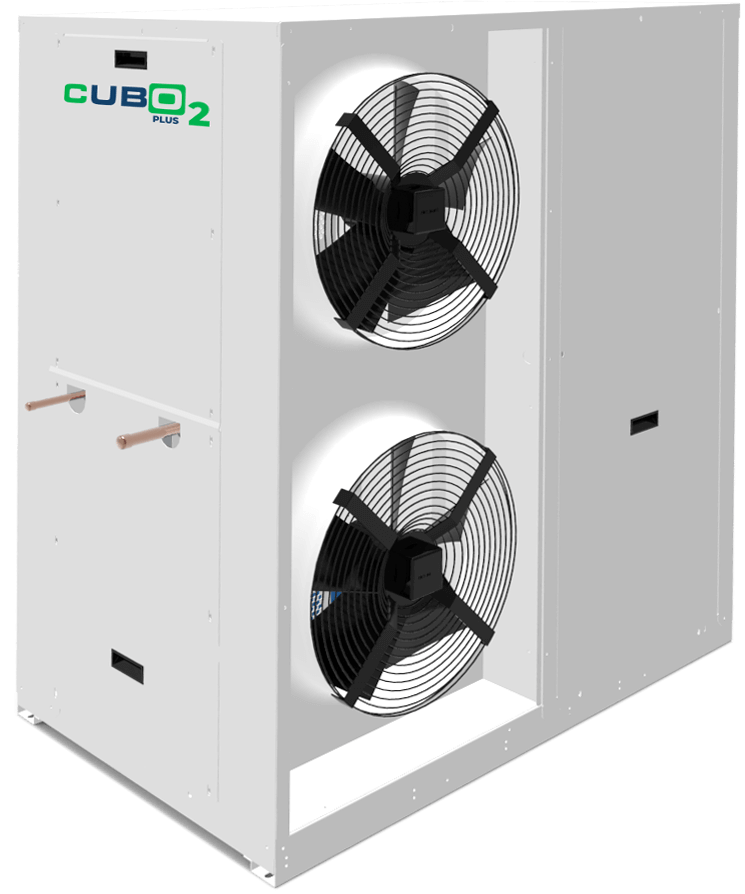

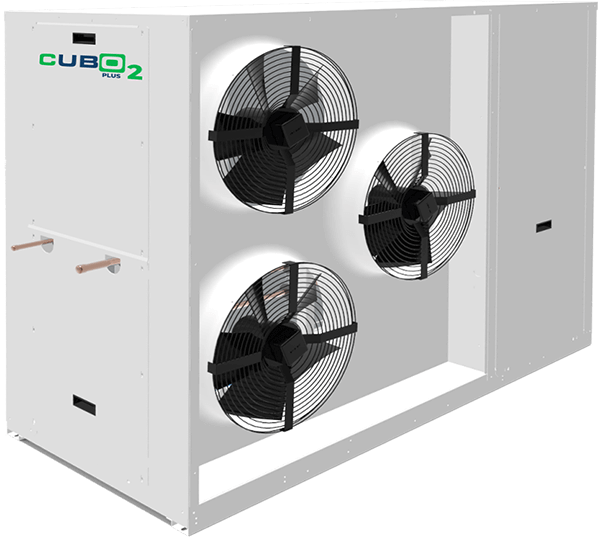

Compact design

The compactly designed unit makes installation and maintenance easy.

Easy to start

The unit is equipped with a gas cooler and a control panel, and is delivered with the programming entered at the time of shipment from the factory, so it can be started easily.

Subsidies such as carbon dioxide emission control measures project costs can be received

In the case of introduction or renewal of the refrigerator system, subsidies such as carbon dioxide emission control measures project costs can be received. (Until 2021)

If you are considering it, please contact us as soon as possible.

Support from equipment selection to installation and after-sales service

Hearing your request and conducting a field survey to propose the optimal plan

- Contact Us

- Hearing / field survey

- Suggestions / Quotations

- Contract

- Please contact us using the inquiry form or by phone (81-0265-71-7172).

- We will hear your request. We will also conduct a field survey if necessary.

- Based on the results of hearings and field surveys, we will make optimal proposals according to your needs.

- We will make a contract if you are satisfied with our explanation and proposal.

Complete installation work, various procedure support, and after-sales follow-up

- Installation work

- Introduction / operation explanation

- Various procedure support

- After-sales support

- Installation work will be carried out in the presence of our designated contractor and our staff.

- After installation, we will explain the operation method to the person in charge of the customer.

- If you are using a subsidy for new installation or renewal, we will support the subsidy application.

- Please be assured that we will take responsibility in case of emergency.

Introducing Sustainable Cold Solutions

CO2 system for medium and low temperature use

Model UMT T MTDX cooling capacity 0.6-8.5kW

Model UMT T BTDX Cooling capacity 0.65 to 6.6 kW

- DC brushless rotary compressor

- Inverter modulation 25-100%

- EC gas cooler fan

- Space-saving type

- K65 connection

- Design pressure 120bar (high pressure side) / 80bar (liquid line) / 80bar (suction)

- CO2 receiver (8L)

- Water-cooled gas cooler

Model UMT T MTDX cooling capacity 1.1-37kW

Model UMT T BTDX Cooling capacity 0.6 to 15 kW

- Semi-enclosed reciprocating compressor

- Frequency control compressor (MT line)

- EC gas cooler fan

- CO2 receiver 15L

- K65 connection

- Design pressure 120bar (high pressure side) / 80bar (liquid line) / 80bar (suction)

- LT inverter

Model UMT T MTDX cooling capacity 0.6-8.5kW

Model UMT T BTDX Cooling capacity 0.65 to 6.6 kW

- DC brushless rotary compressor

- Inverter modulation 25-100%

- BPHE gas cooler

- Space-saving type

- K65 connection

- Design pressure 120bar (high pressure side) / 80bar (liquid line) / 80bar (suction)

- CO2 receiver (8L)

Introduction results

- Food supermarket

- Convenience store

- Beverage maker Beverage wholesaler

- Warehouse company

- Low temperature air conditioning in food factories

Lab tour where you can see the actual machine

There is a laboratory that installed the actual machine in the factory in Ina City, Nagano Prefecture so that you can see and consider the actual machine.

We are always available for tours, so if you wish, please use the inquiry form.

Please feel free to contact us for any questions, request for quotation, repair or after-sales support.